- Home

- Thermal Management

- Heaters

- Aluminium Foil Heaters - IP68

- Cartridge Heaters

- Cast Heaters

- Ceramic Knuckle Heaters

- Coil Heaters, Coiled Heater Bands and Nozzle Heaters

- Custom Heaters

- Drum Heaters

- Finned Air Heaters

- Flanged Heaters

- Flat Tubular Heaters

- Flexible Tubular Heaters

- Heating Cables, Crankcase Heater

- Immersion Heaters

- Mica Insulated Heaters, Mica Band Heaters, Mica Plate Heaters

- PTC Self-regulating Heating Elements

- Silicone Mat Heaters, Wire Wound, Etched Foil

- Tape Heaters

- Thick Film Heating Elements

- Tubular Heaters

- Temperature sensors

- Temperature controllers

- Products

- Contact

Thick Film Heating Elements

Our thick film heating elements are used in a number of applications, such as in household appliances, railway transport, gastro-facilities, machinery and many other industrial sectors. The thick film heating elements are produced in large volume, as well as special single-piece production.

Thick film heating elements are suitable for contact heating of plan surfaces, and can be used to heat other mediums through a vessell. We have recently introduced another product range of thick film heating element on a tube, which may be used in applications requiring heating of flowing liquid.

BENEFITS OF HEATING BY THICK FILM HEATING ELEMENT AS COMPARED TO OTHER HEATING METHODS

- The element is on a flat sheet thus ensureing significantly better heat transfer to flat wall as compared to tubular element

- Quick temperature rise time - energy savings

- Easy assembly and disassembly - cost savings

- Possible high surface load - tens of W/cm2

- Inner surface of heated vessel remain smooth and easily washable

- Very suitable for heating of aggressive liquids

- No need to discharge the vessel content during maintenance

- Heating through sufficiently large area may effectively prevent burning of content to the vessel surface

Main Application Areas

- Household electric appliances

- Mini-breweries

- Medical and laboratory devices

- Industrial vessels and storage tanks

- Gastro-facilities

- Automotive

Production Technology

Thick film heating elements are manufactured in a completely different way than ordinary tubular heating elements. A thick film heating element consists of a stainless steel substrate (plate), on which an insulation layer (meets the requirements for dielectric strength) is printed, then a layer of resistive paste, followed by a contact and connective layer, and finally all these layers are covered with top insulation layer (providing protection against mechanical damage). The individual layers are applied by screen printing and each layer is dried and fired afterwards. Maximum protection from dirt and dust is essential through the whole production process. Production runs are in air-conditioned areas meeting the requirements for rooms with high air purity class.

Thus precisely manufactured thick film heating elements feature a quick temperature rise, an extremely low thermal capacity and minimum temperature fluctuations. Their high efficiency of 70 - 95 % depends on the mode of operation (direct or indirect heating).

The substrates are made of stainless steel according to standards AISI 430 (DIN 1.4016), AISI 304 (DIN 1.4301), AISI 444 (DIN 1.4521) and Titan Grade 2 (DIN 3.7035) are used. The substrate (printing area) must be flat, but can be of various shapes and can contain openings manufactured in advance (before the printing process) if required.

The elements operate at standard line voltages (up to 400 V). Thick film heating elements feature very high surface power density - up to tens W/cm . Nevertheless, their operation conditions should be adjusted according to the particular application - adequate heat transfer should be provided so that the surface temperature does not exceed 300 °C (requirements for higher temperature must be consulted with our Technical Department).

Thick film heating elements feature a significant PTC effect (its resistance rises with rising temperature, so its power decreases consecutively). Thus, resistance at room temperature and nominal voltage are specified as technical parameters for thick film heating elements.

In most cases the heating is solved by use of a standard-manufactured thick film heating elements however we can produce custom specific heaters if required just ask our sales team for further information.

Examples of realised applications

- Mini-brewery

- Round-bottom vessel

- Heating of bottom by heating elements and walls by band heaters

- Machine part heating

- Liquid bath

- Air heating

- Oil bath

- Vessel with aggressive liquid

- Heating in production line

- Thick film heating element with control

- Detail of thick film heating element with control

- Waxing iron

Thick film heating elements (PDF datasheet)Product enquiry and further information (Contact us form)

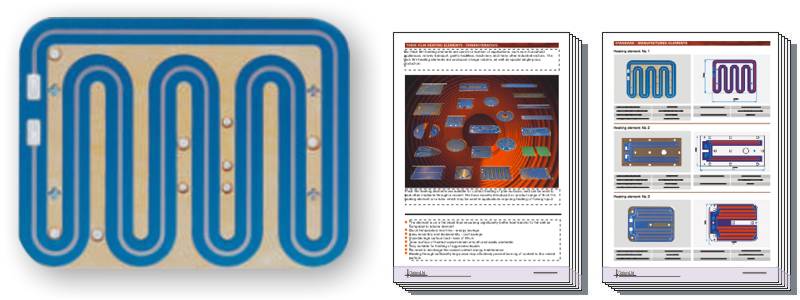

Heating element No. 1

Thick film heating elements (PDF datasheet)Product enquiry and further information (Contact us form)

Input power at 230V

- 680 W

Input power range at 230 V

- approx. 600 - 1200 W

Input power tolerance

- +5 / -10 %

Substrate outer dimensions

- 131 x5 0909 mm

Substrate material

- Stainless steel

- DIN 1.4016, AISI 430

Substrate thickness

- 1.5 mm

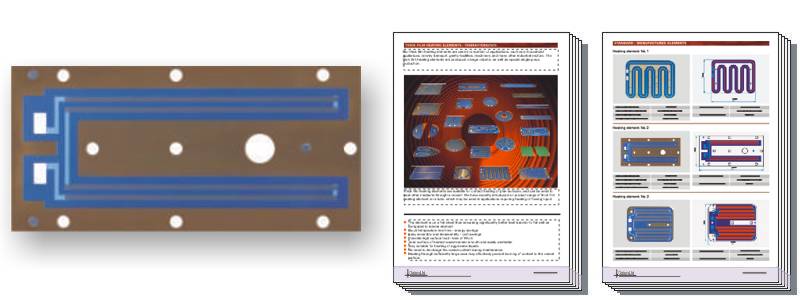

Heating element No. 2

Thick film heating elements (PDF datasheet)Product enquiry and further information (Contact us form)

Input power at 230 V

- 1200 W

Input power range at 230 V

- approx. 600 - 1200 W

Input power tolerance

- +5 / -10 %

Substrate outer dimensions

- 167 5x 080 mm

Substrate material

- Stainless steel

- DIN 1.4016, AISI 430

Substrate thickness

- 2 mm

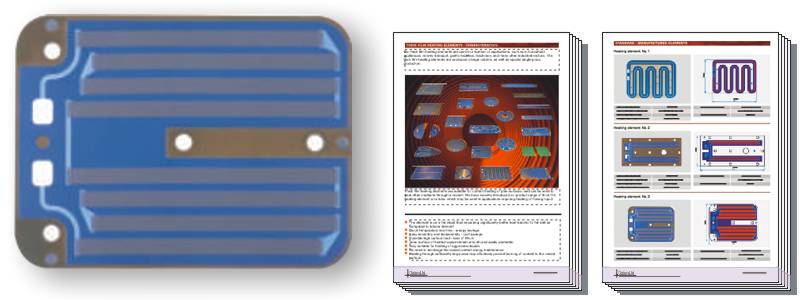

Heating element No. 3

Thick film heating elements (PDF datasheet)Product enquiry and further information (Contact us form)

Input power range at 230 V

- 2000 - 4000 W

Input power tolerance

- +5 / -10 %

Substrate outer dimensions

- 131 x 99 mm

Substrate material

- Stainless steel

- DIN 1.4016, AISI 430

Substrate thickness

- 2 mm

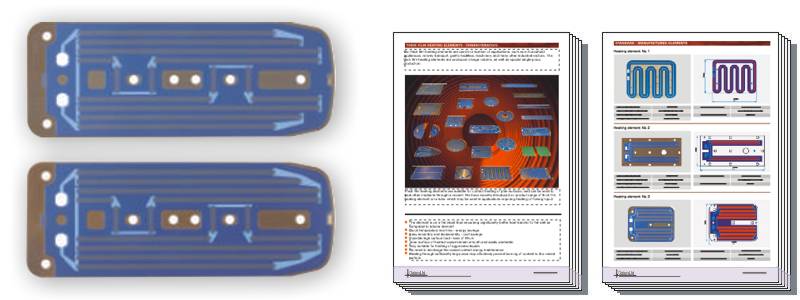

Heating element No. 4

Thick film heating elements (PDF datasheet)Product enquiry and further information (Contact us form)

Input power range at 230 V and 110 V

- 500 - 1000 W

Input power tolerance

- +5 / -10 %

Substrate outer dimensions

- 151 x 57 mm

Substrate material

- stainless steel

- DIN 1.4016, AISI 430

Substrate thickness

- min. 2 mm

Heating element No. 5

Thick film heating elements (PDF datasheet)Product enquiry and further information (Contact us form)

Input power range at 12 - 48 V

- 5 - 200 W

Input power tolerance

- +5 / -10 %

Substrate outer dimension

- 75 x 70 mm

Substrate material

- stainless steel

- DIN 1.4016, AISI 430

Substrate thickness

- min. 1 mm

Heating element No. 7

Thick film heating elements (PDF datasheet)Product enquiry and further information (Contact us form)

Input power range at 230V

- 1000 - 2000 W

Input power tolerance

- +5 / -10 %

Substrate diameter

- 167 mm and 200 mm

Substrate material

- stainless steel

- DIN 1.4016, AISI 430

Substrate thickness

- min. 1.5 mm

Heating element No. 8

Input power range at 230 V

- 1000 - 2000 W

Input power tolerance

- +5 / -10 %

Outer tube diameter

- 20 mm

Tube material

- stainless steel

- DIN 1.4301, AISI 304

Tube wall thickness

- 1 mm

Product enquiry and further information

We would be delighted to offer free application advice, technical information on products, free quotations and delivery information.